Sheet Metal Laser Cutter for Dummies

Sheet Metal Laser Cutter for Dummies

Blog Article

When it comes to fashionable producing, the precision and efficiency of laser cutting engineering are certainly recreation-altering. Laser cutting devices have revolutionized industries by furnishing a technique of cutting elements with unparalleled precision. When you’ve at any time marveled for the intricate designs on steel or puzzled how intricate styles are generated so seamlessly, it’s frequently the function of the industrial laser slicing machine.

Permit’s begin with the basics: a laser cutter is really a Instrument that employs a laser beam to cut supplies. This beam is very centered and generates superior temperatures to melt or vaporize the material, generating specific cuts. In contrast to conventional solutions, which could use mechanical blades, a laser cutter offers a standard of accuracy that is almost unmatched. Envision seeking to carve a delicate pattern which has a hammer—Plainly, a laser cutter is lots additional refined!

Industrial laser chopping can take this technological innovation to the subsequent amount, supplying methods for big-scale operations. These machines are created to handle hefty elements and higher output volumes, guaranteeing that even quite possibly the most demanding tasks are concluded with superior effectiveness. Think of it since the difference between employing a precision knife for fragile paper crafts and a powerful noticed for slicing via thick wood.

What Does Sheet Metal Laser Cutter Mean?

In the world of CNC laser reducing, the “CNC” stands for Pc Numerical Control. This engineering permits automatic and extremely precise cuts by adhering to electronic types. When you’ve at any time employed a pc to draw then viewed that drawing arrive at life, CNC laser cutting functions in a similar way, translating digital styles into physical cuts. It’s like getting a virtual designer Using the precision of the laser.

In the world of CNC laser reducing, the “CNC” stands for Pc Numerical Control. This engineering permits automatic and extremely precise cuts by adhering to electronic types. When you’ve at any time employed a pc to draw then viewed that drawing arrive at life, CNC laser cutting functions in a similar way, translating digital styles into physical cuts. It’s like getting a virtual designer Using the precision of the laser.The Ultimate Guide To Industrial Laser Cutting

Precision laser reducing just isn't just about earning cuts; it’s about creating them correct each and every time. The laser might be adjusted to realize diverse depths and widths, making sure that every Minimize is precisely the place it needs to be. This can be important for applications where even a slight deviation could lead on to major concerns. Visualize it being a surgeon’s scalpel, the place precision is not simply critical but Certainly vital.

Precision laser reducing just isn't just about earning cuts; it’s about creating them correct each and every time. The laser might be adjusted to realize diverse depths and widths, making sure that every Minimize is precisely the place it needs to be. This can be important for applications where even a slight deviation could lead on to major concerns. Visualize it being a surgeon’s scalpel, the place precision is not simply critical but Certainly vital.Laser slicing equipment comes in various sorts, Just about every customized to certain requirements. Irrespective of whether You'll need a smaller desktop model for passion tasks or a huge industrial device for factory use, there’s a laser slicing Alternative to choose from for you. These machines vary in ability, speed, and capabilities, so it’s important to choose the suitable just one to your specific software.

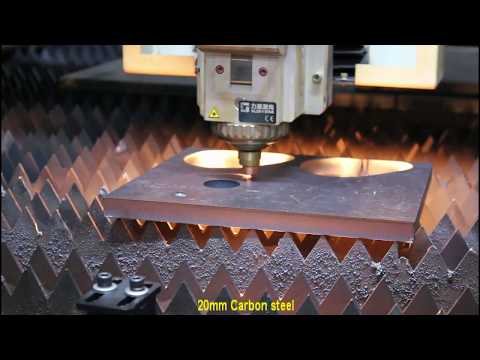

Sheet steel laser cutters are a special group of laser chopping machines created specifically for reducing metallic sheets. They can be broadly used in industries ranging from automotive to aerospace because of their ability to handle metal with precision and pace. Photograph a sheet of steel just like a blank canvas, as well as the laser cutter as the artist who makes elaborate and beautiful patterns with remarkable accuracy.

Laser reducing solutions are A further essential facet of this engineering. Not Anyone wants to invest in their unique laser cutting machine, particularly if they only want occasional cuts or explore here deficiency the Place for this sort of equipment. Many businesses supply laser slicing solutions where you can mail your patterns and possess them cut with superior precision. It’s like outsourcing your artwork to a skilled Specialist.

Laser slicing programs integrate a variety of elements to provide the desired effects. Within the laser resource for the cutting bed, and also the Management computer software, each A part of the program is effective with each other to make sure a flawless operation. It’s a little similar to a symphony orchestra, where each musician has a certain part, and only by working alongside one another do they develop a harmonious performance.

With regards to laser chopping engineering, the evolution has been immediate and remarkable. To begin with made use of largely for chopping metals, these devices now handle a wide array of materials like plastics, Wooden, and perhaps fabrics. This flexibility can make laser reducing technological know-how a valuable Software in a great number of industries. Imagine having a Swiss Army knife which will manage just about any material—This is certainly what modern laser cutting engineering offers.

The accuracy of laser slicing equipment is really impressive. They can Slice components to in just microns on the meant layout, making sure that even essentially the most intricate particulars are preserved. This standard of precision is particularly beneficial in industries in which exact measurements are very important. Visualize it because the difference between a personalized suit and off-the-rack clothing—the match is simply best every time.

How Precision Laser Cutting can Save You Time, Stress, and Money.

Yet another advantage of laser slicing know-how is its performance. Unlike traditional chopping procedures Which may demand many actions or resources, laser chopping generally completes the process in a single go. This not just speeds up manufacturing but will also decreases materials squander. It’s like aquiring a superior-velocity teach that receives you on your destination promptly and competently with no needless stops.While in the context of industrial apps, the robustness of laser chopping equipment is very important. These machines are built to endure the calls for of ongoing Procedure, usually running 24/seven in superior-quantity settings. Their durability makes certain reliable general performance and trustworthiness, which can be important for protecting creation schedules. It’s like having a major-obligation truck that reliably provides merchandise working day immediately after working day.

Among the list of impressive aspects of laser reducing is its capability to create clean and exact edges. This reduces the need for publish-processing, like sanding or ending, that may be time-consuming and expensive. The result is actually a easy, completed products That always calls for minimum more operate. Envision ending a craft challenge without glue spills or tough edges—it’s that clean!